Sunday, December 11, 2011

Update - Throttling the DMLS

Just a short note - I tested the DMLS chamber in the throttling configuration. All the previous tests were with on/off solenoid valves. Thrust level reached approximately 80% before the test was stopped when the stand started rolling.

Saturday, August 13, 2011

Testing Update

The DMLS chamber has accumulated 18 starts and 152 seconds of firing time. The last test was 31 seconds in duration reached something close to steady state according to the regen coolant temperature measurement.

The graph shows the measured temperature of the N2O in the regen coolant jacket near the exit. Notice the temperature actually decreases in the last few seconds of the test, even though the propellant flow rates are constant through out the entire test. Notice also that the N2O is a gas at that temperature.

Some of the early tests ended with glowing red sections of the chamber. I think there are several things going on here. One is that there are some manufacturing flaws in the injector that result in a non-symmetric injection patter, which I think is making locally hotter combustion. Another is that, at low chamber pressure conditions, the regen design is really marginal - I spent most of my time making sure it would work well at the 100% thrust level. I think the main issue is that the channels in the barrel section of the chamber are spaced too far apart.

When I first saw the red-hot walls, my first concern was that the N2O was decomposing in the coolant channels. However, based upon the regen temperature measurements this does not seem to be the case. Also, the pictures and video indicate that the hottest wall sections are between channels which is the opposite of what you would expect if the nitrous was decomposing into N2 and O2 at 3000 degrees Fahrenheit.

The next tests will be focused on step-wise increasing the chamber pressure to the 100% level and decreasing the O/F ratio. Once I have the operating limits mapped out, I'll decide whether to revise the design, or move to the next step of the project.

Saturday, July 23, 2011

Testing Update

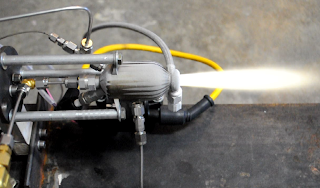

I've finally fired the DMLS regen chamber! Two tests so far of 2 and 3 second duration at 50% power level and relatively high O/F ratios

Here's the video of the second test:

What I've demonstrated so far-

- You can actually print a "tube stub" in your motor and use a Swagelock nut/ferule set to attach instrumentation

- My additional measurements (temperature and regen pressure) are working well.

- The direct spark ignition with the D514A coil is working.

- There don't appear to be any blockages or leaks in the regen jacket.

- C* efficiency is reasonably high - approximately 90%.

The big question still remains to be answered - will the motor survive long duration operation as the temperatures reach steady state.

Saturday, June 11, 2011

No Testing Yet

Everything is ready to go on the stand - all the instrumentation is connected and checked out - I just haven't made the time to buy another nitrous bottle and test. I'm measuring the following in this setup:

N2O supply pressure

Propane supply pressure

Regen jacket pressure

Regen jacket temperature

Chamber pressure

Oxidizer flow rate

I have a flow meter installed on the fuel side, but the flow rate will be too small for the meter. I'd love to measure fuel flow as well, if some one has a 0-1 gpm turbine meter that they're not using...

The injector for this chamber is a pintle configuration based upon the design I showed in previous posts. I had a local shop EDM the 8 0.014" injector holes in 1/8" instrument tube and then pinched off the end of the tube.

This is a picture taken through a microscope showing the EDM holes. The price was extremely reasonable - drop me a line if you interested having some small hole EDM work done.

Hopefully I'll be able to do some limited ignition testing soon.

Friday, March 4, 2011

What Its All About

Engineering is about making things. For me, it is incredibly satisfying to conceptualize something and then make it exist and work as intended. I think that is why 3D printing technologies have captured my imagination - they are a step towards a Star Trek style "replicator". They offer the promise of shortening the loop between concept and reality.

I've been dreaming of different projects for the DMLS process for over three years now. A couple weeks ago, I took the plunge and had a chamber printed in 15-5 stainless steel. The first picture is the CAD, the second obviously the manufactured result. It really is a thrill to send electrons across the country and open a box a few days later to find the electrons made metal.

Now, some of you are saying "but you can do that with conventional machining" and you are right. But having a part machined has a certain activation energy - it requires a non-trivial amount of effort and skill. 3D printing is still not effortless - there are rules about what geometries are printable and of course you have to be able to generate a 3D model of your part. But the barriers are much lower. And there is also the fact that it can make geometries which are expensive or even impossible with conventional manufacturing techniques. It is still expensive - my part cost 4 figures even though it is quite small. In fact, it represents the larges single purchase I've made to date on my rocket hobbies. But as with any other process, buying in quantity is cheaper.

Everything in grey in the CAD picture came as is from the DMLS machine. As you may notice it is a regen chamber and instrumentation ports are integral to the DMLS part. Threads for the spark plug and inlet fitting were printed slightly undersized (extra metal) and then I cleaned them up with a tap by hand. The part came out more or less as I drew it, although there were some imperfections that affect the design. I'm talking with the vendor about ways to modify the design to avoid those problems on future builds.

Testing will follow soon. Had this been my "day job" I could have tested the motor the same day that it was delivered. Installing fittings and tapping out the holes took about an hour of slow work. The mounting ears fit directly on my stand as is. Unfortunately, life is a bit busy these days for me. And I still need to get some thermocouples for coolant temp measurements.

Questions welcome!

Subscribe to:

Posts (Atom)