Sunday, December 12, 2010

Saturday, November 20, 2010

The Poor Man's Pintle

A bit of a delay since the last post - quite a lot of things going on outside of blog land.

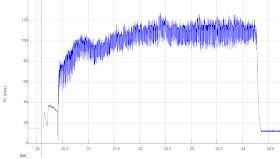

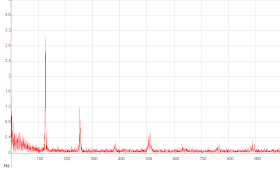

Two posts ago I showed a method for sealing off the end of a stainless tube. But to what end? I was brainstorming on a easy way to make a pintle injector. I took the tube shown in the previous post and drilled 8 holes in the end. The result is less than optimal because my mill's spindle is really too slow for the size hole I need. But the result was promising.

These tests were run with water in the center and air on the annulus.

Sunday, September 5, 2010

Data Data Data

Friday, August 27, 2010

Tubes

Lenox Laser makes some really nifty orifice fittings. I recently ordered some of the 1/4" tube fittings because I wanted some orifices for my igniter that are smaller than the 0.014" available as flare jets.

The 1/8" tubes got me thinking about another project and so I was looking at buying some of the smaller orifice fittings and modifying them for my own use. The problem was they really only have up to 3" lengths without added cost. And even at $30 they seemed a bit pricey to buy and carve up. A search of the web found no easy source for the blanks they make so I tried my hand at making one myself.

I first tried to make a mandrel using a 1/8" ball end mill. That didn't work particularly well. I had a ball bearing spinning tool for the lathe left over from another project, so I tried it.

.JPG)

It worked very well. The tube in the picture below is my very first attempt with the technique. I was anticipating having to spot weld the end but it is water tight to 60 psi which should be good enough for what I have in mind.

Monday, August 23, 2010

Additional Testing

I modified the nozzle to a slightly larger throat area and added a diverging section. This test configuration had a 0.014" propane orifice, a 0.027" N2O orifice, and a throat of 0.201". It was running slightly lean at a chamber pressure of 110 psi. I plan to mount it to the thrust stand and get some performance data next.

Friday, August 13, 2010

Nitrous Propane Rocket Igniter

Second video, slightly smaller orifice size, chamber pressure of 110 psi.

More Igniter Testing

I am testing various nitrous oxide orifice sizes. This one generated about 135 psi of chamber pressure. And the video is in focus this time.

Sunday, August 8, 2010

Loooooooong Time

Sunday, March 21, 2010

Engine Testing

Here is a video from the first day of "full up" engine testing. You can see that the igniter works and the fuel valve in motion. You can also see that when the main valves open, the combustion efficiency is pretty poor.

Sunday, March 7, 2010

Sparks!

I realize that I've probably done this topic to death but I spent a lot of time last fall on ignition systems.

So, here are a couple of photos of sparks. I was trying to capture the visual difference between the CDI and induction style systems.

The first photo is with the LS2 coil and a surface gap plug. This photo is pretty close to what you see with the naked eye, the purple color is very distinctive.

This photo is with the RCEXL system driving a standard small engine plug with the electrode cut off. The resulting gap is enormous and none of the induction systems produce enough voltage to jump that gap even at atmospheric pressure. The CDI system delivers less energy per spark than the induction systems I've tried. The resulting spark is pencil thin and bright white.

Sunday, February 28, 2010

February

The Franken-chamber has been tested with the torch igniter. The igniter has been very reliable and easily lights the main chamber. It is easily 10 times bigger than necessary and makes over 10% of the main engine's rated thrust running by itself. However, the size of the igniter is set by the smallest practical orifice size which is 0.014" in the NOS flare jets I am using. If I switched to vapor propellants, it could be made much smaller while making the plumbing much more complicated.

Testing of the main chamber has shown the combustion efficiency is extremely poor. The easiest approach to improving efficiency is to increase chamber length. With the stainless steel chamber, it was easy to cut the nozzle end off with the band saw and weld in another barrel section. The result is sort of comical looking - yet another testament to the limits of scaling rocket engines

I hope to be able to test again soon. In the meantime, I've already starting working on the design of the next engine as this one has about reached the end of its patchwork life.

Wednesday, February 10, 2010

A Non-update

I've been testing the Franken motor as well as another igniter for a different application. Finished upgrading the test stand hardware and software with flow meters for both oxidizer and fuel. That has already been very useful as I was able to accurately determine the O/F ratio the igniter is running. It will light as rich as 7:1 but runs very rough. Smoothest operation seems to be right around stoichiometric at 10:1 or a bit leaner.

I've also been working on an avionics experiment that is coming up this spring. More on that to come soon.

Saturday, January 16, 2010

Hybrid Tips

At 8 bars chamber pressure and 3.5 nozzle area ratio, a nozzle is horrifically over expanded. An over expanded nozzle will contribute significantly to poor ISP performance

c* is a better measure of combustion efficiency, being a function of mass flow rate, chamber pressure, and nozzle throat area. At low chamber pressures, use frozen chemistry rather than equilibrium in PROPEP.

It is common practice in hybrid motor design to include a "pre-chamber" upstream of the fuel grain - it will help improve performance and stability.

Back when I was doing N2O/HTPB hybrids, I measured c* efficiencies from 50% to 84% all with the same hardware - changing mainly fuel grains.

Friday, January 15, 2010

Ozone Part II

AC Delco Coil Near Plug - aka "The LS2 Coil"

This is where it gets interesting. The OEM application for this coil is the GM LS2 V8, powering Cameros, Corevettes, and various GM trucks and SUVs over the past decade (PN# D514A). It is termed coil near plug because they are mounted on the valve covers and there is one for each cylinder. The complete setup with coil, weatherproof pigtail, and sparkplug lead can be had off ebay for around $45 (from different vendors, of course). This makes it the second most expensive setup but I think well worth it.

This coil is immensely popular with the DIY electronic engine control community. You can read all about it on this page. The most attractive feature of this coil is that it can be triggered with almost any signal that rises above about 3 volts. In automotive lingo it has a "built-in igniter" meaning the power transistor, protection diodes, and noise suppression components are in the coil package itself and so it can be triggered by a low-current logic level signal. It even has a dwell limiting feature which keeps the coil from burning up if the trigger pin is held high too long. I am triggering it directly from a logic pin on my 3.3V micro-controller - not a single component between the micro's pin and the coil connector. The optimum dwell time is about 5 ms at 12V, which is perfect for a 50% duty cycle at 100Hz - I've run it up to 200 sparks/second with good results as well. Spark energy is visibly higher than the other three inductive systems with a fat, purple spark. It pulls a healthy 2.9 amps at 100 sparks/second and should run on power from 6-16 volts with no issues. When you throw in OEM automotive engineering and reliability (even if it is from GM), this system looks really attractive.

RCEXL CDI System

This is a capacitive discharge ignition module for radio controlled small engine applications. Like the LS2 coil, it may be triggered via a 3.3V low current signal. It is designed to operate over a more narrow range of voltage (4-6V). As a hobby system, I would expect that the engineering, quality, and durability is somewhat less than the LS2 coil. However, it is a CDI system and should deliver higher voltage to the plug. It pulls about 0.5 Amps at 5V and the sparks are pencil thin and bright white. The spark plug cap has a unique metal shell and shield high voltage cable that grounds the ignition system directly at the plug and helps to reduce radiated noise. However, as I discussed in a previous post, this ignition seems sensitive to shorts of the spark plug - it is far more likely to cause processor resets with a short than the other inductive systems. It weighs only 150 grams with cable and boot which is about half of the LS2 coil setup.

Wrap Up

I think the LS2 setup is the obvious winner for most applications given the level of engineering, simplicity of interface and integration, and operating voltage range. It might save a pound over a MSD type system and would probably provide better reliability. The RCEXL system might be preferred if you were on a severe weight or power budget or you were trying to ignite mixtures at high pressures (+200 psi). For my igniter, which lights at just over ambient and runs at 100 psi, all four options ignited with no measurable differences.

Tuesday, January 12, 2010

The Smell of Ozone

As I mentioned in my previous post, I tried out several different spark ignition systems as potential replacements for the C&H CDI box I have been using.

From left to right are a spare coil for my '76 Ford Pickup, a Tecumseh small engine coil, an AC Delco "coil near plug" module, and the RCEXL CDI System. The first three are all designed to be used in inductive discharge, or Kettering, ignitions systems. Most of the testing I did was at 100 sparks per second. I did not measure spark energy or current as I don't have the equipment necessary.

Ford Can Coil

This is a fairly standard coil used on almost any older car with a distributor and points setup. One can get a coil like this at any automotive parts store by asking for a coil for a random car built before 1975 or so. It is easy to drive with almost any transistor per advice from Thomas McNeill. I actually used a power MOSFET that I have been using to control solenoid valves. I tried this coil while I was waiting for others to ship because I had it already on the shelf. I wouldn't recommend using it otherwise. It generated the weakest spark at the lowest cost of the four options.

Tecumseh Coil

This coil was tested by the folks over at the Rocket Work Bench website (PN# 30560A). It was inexpensive and gave fairly good results so I thought I'd give it a try. As was noted before, it gets fairly warm, especially running at 100 sparks/second. That is not really surprising as it was probably designed for around 3000 RPM or 25 sparks/second. It does seem to produce a fairly energetic spark and is triggered the same as the can coils.

I'm going to make this a multi-parter because its late and I'm being paged.

To be continued ...

Saturday, January 9, 2010

Configuration Control

Those of you who work with software know what SVN and CVS are. And you've probably found yourself in the position of having code that used to work several versions ago, but you've messed it up and you pull your hair out trying to figure out what went wrong. So, what you do is go back to the last working version and start over, making smaller changes.

It sure would be nice to have SVN for hardware.

I posted a video of my torch working well. I then welded it onto the chamber for testing and found that every time the spark triggered, the microcontroller would reset. In the standalone configuration, I had never experienced a reset. Unfortunately, I had made several changes at once that contributed to the resets.

First, I had made a new custom PCB to replace the protoboard I was using previously. Because the board was new, I focused on it as the source of the reset issue. I did eventually find an issue with the ground plane design which was contributing to the resets (It is the first PCB i had ever designed). However, the resets continued but now they only occurred when propellants were flowing in the igniter!

At this point I began to suspect that my ignition box was bad. I have been using a CDI box designed for RC engines for some time now and thought perhaps it had been damaged. After perusing this page: http://rocketworkbench.sourceforge.net/igniter/igniter_blog.html and talking with some of my fellow Arocket-eers, I thought I would try a simple inductive coil setup. I bought via mail several different hardware options including a replacement for the CDI I had been using (I'll post a follow on about all the different ignition systems).

The various setups still suffered from similar problems - at this point I was baffled! Eventually, I made an Edisonian discovery on the bench - if the spark plug electrode was shorted to ground when the coil attempted to fire, it would cause a reset every time. Placing a bead of water over the electrode and touching the ground had the same effect.

As it turns out, when I welded the torch to the chamber, I had welded a new spark plug bung onto the igniter. This was done as an afterthought - I wanted to clean up the multiple bungs I had welded onto the igniter when trying different threads for different plugs. My intention was to maintain the exact spacing, but I must have made the new bung slightly shorter than the original.

I added a spacer to the bung to move the tip back just a little --- and everything worked just as it had before. I inject both propellants as liquids and apparently the spark plug tip was seeing too many liquid droplets, causing the spark to not fire and the resets. All of the ignition systems work just fine in this configuration, including the original CDI box.

So, SVN for hardware would have saved me tons of time, headache, and grey hairs.

Stay tuned for a post about ignition options.

.JPG)